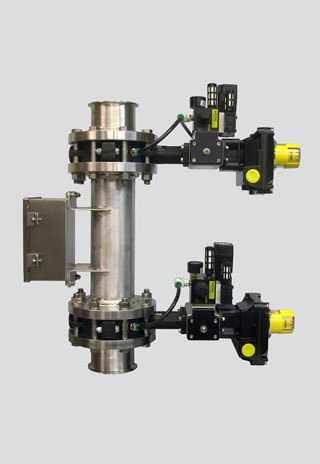

Double Dump Valve Assembly

The Double Dump Valve Assembly by Posi-flate is a low cost and low maintenance alternative to the traditional rotary airlock feeder and provides a positive seal that that can accommodate either full vacuum or pressure up to 100 PSIG. The air-operated seat inflates to provide a long-lasting high integrity seal and easily handles high cycling of dry granular or fine powdered materials.

The seat automatically compensates for wear when it inflates against the disc, extending valve life considerably. The Posi-flate Double Dump Valve Assembly is available in carbon steel and stainless steel in sizes from 2 inch (50mm) to 30 inch (750mm) diameter and in any length desired. Other materials of construction are available upon request.

Product Applications

Purpose: Double Dump Valve Assembly Unloading Sodium Borate/Boric Acid from an Evaporator/Dryer

Purpose: Double Dump Valve Assembly with Ferrule Connection for Spray Dryer Inlet Handling Natural Organic Food Powders

Purpose: Double Dump Valve Assembly with Ferrule Connection Loading Catalyst into a Fluidized Bed Jet Mill

Purpose: Double Dump Valve Assembly with Ferrule Connections Discharging Titanium Silicate from a Spray Dryer

Purpose: Double Dump Valve Assembly for a Dust Collector Discharge Handling Phenolic Resin

Purpose: Double Dump Valve Assembly Loading Toner Powder into a Toner Classifier

Purpose: Double Dump Valve Assembly Discharging Catalyst from a Dust Collector

Purpose: Double Dump Valve Assembly for Dust Collector Discharge Handling Toner Powder

Purpose: Double Dump Valve for Discharging Tobacco Powder from a Dust Collector to a Storage Bin